Spring on the Farm, 2025

New Project and Old Projects

A quarterly update on the farm today, as some of the readership finds this interesting. Thanks for reading! and if you are new here and you enjoy the update, please support my work by clicking the button below:

Today as I write it is raining, and windy and chilly. I opened the door to the lamb’s shelter and gave them some grain. Here in Northern Michigan we’re still waiting for the grass to green up again and the forage to get going. It’s been a very average spring so far, not ahead of schedule or behind schedule, just average and fine by me.

This will be the new pasture - I just overseeded it last week and it’s already starting to sprout:

I’ve been pruning the orchard, and I’m down to about 10 trees (from 800 - humble brag). I can only do it about 4 hours a day and then the aches become more noticeable; “the spirit is willing, but the flesh is weak.” I also planted, as God is my witness, the final 30 trees of my life! I’m getting to old for it, but our friends at Van Well Nursery out in Washington state had some excellent Yarlington Mill trees so I filled up a few ‘holes’ in the orchard:

The lambs are doing well, now two weeks in their new home. They’ve become more easy around me, and of course it doesn’t hurt that I’m the one to feed them grain and hay every day. The ducks arrive end of the month, and that’s one my jobs this week to get their shelter ready with heat lamps, straw and pine shavings. Here are the boys, Tecumseh and Ulysses:

Fun fact about sheep: They can pee while they walk, a trick of which, even in my athletic youth, I was incapable!

Also at the end of the month the new bees arrive. I made myself a beelining box just for fun, but I’m running out of time to find wild bees. At any rate, I have a few new colonies coming with queens and will give it another try this year. I also setup new supports for the hives. I’ve decided to store them over the winter in the new apple cidery building, so their new legs will make that easier as I can pickup the hive with the tractor forks.

Speaking of the new apple building, the cidery as it were, the work will begin early next month. I have prepared the area and will start excavation as soon as possible. The machines for processing the apple into juice will shortly be on their way, manufacturing is complete, and the construction will start shortly. I also ordered the container for washing the apples. It comes out of Idaho, 50” wide, 100” long and 48” high.

The other piece that I purchased this spring is a bin dumper. This is an hydraulic machine that can lift a 800 lbs. box of apples and dump them, without the bin, into the washing tank. I lucked out in that I was able to find a used one online in an auction and paid about a third of the price of new. Still it was a hefty charge.

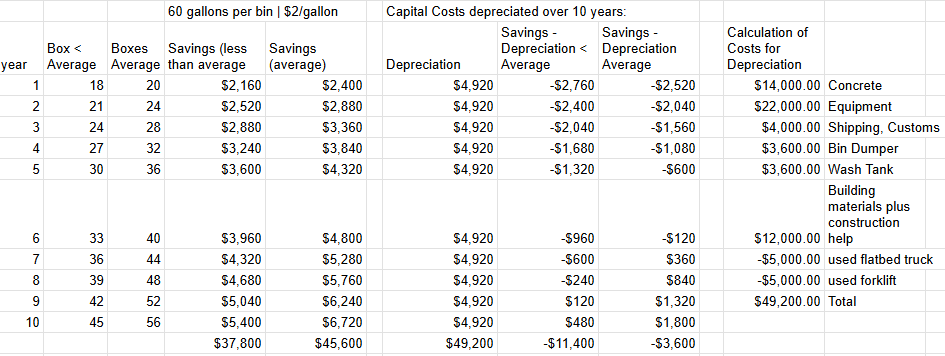

Is it all worth it? New building, new machines, washing tank, and all the associated work? I don’t know really, it’s a toss up. Probably will not pay itself off in under 10 years. Here’s how I put together a small spreadsheet to give myself a better picture of what’s happening (I explain below):

I setup two estimates, one low (< average) and one average. Each Box or Bin of apples has about 60 gallons of juice. I pay $2/gallon to have a local firm process the apples into juice. My orchard is still very young so I also anticipate that in the future boxes of apples increase by 3 or 4 boxes a year. As the number of boxes increase the saving from processing myself instead of outsourcing the processing increases. This year, I will save somewhere between $2160 and $2400.

BUT, I also have more costs, associated with the new cidery and the new equipment for processing. I added up all these costs, which I will pay this year, and then divide by 10 so I can expense them over ten years (this is called depreciation). I then subtracted the annual depreciation from the Savings I will have each year by processing the apples myself.

For example, if I have an average year this year I should have 20 boxes of apples, which would cost me $2400 to have another firm process (20 boxes x 60 gallons per box x $2/gallon). But as I’ll be processing myself, I will save the $2400, but have the $4920 in depreciation to pay instead. It will only be in year 7 that, on average, I will start to see positive cash flow from this investment, and possibly year 12 before I am whole again, meaning the investment has paid off and I am now altogether in the black!

So after 10 years, if my production is below average I will be behind by -$11,400. But if it is average I will be behind by only -$3600. If I have some above average years I may break even after 10 years! I’ll keep you updated how this goes!

One other note, if I had continued to outsource processing, I still needed to make a couple of large purchases: a flatbed truck for box transportation and a forklift to load the truck, which I would have tried to find used, and the $5,000 I’m recording for each is just a low balled guess. They could be more like $7,500 to $10,000 each.

The ducks came on Thursday of this week. Blaine’s Farm and Fleet does a nice job, working with Cackly Hatchery, to bring in poultry. The birds are all setup in their new home with several warming lights - it’s still in the 30’s here at night - and lots of food and water. We saw a report the other day of the huge increase in the number of people raising their own birds. I had no idea when I first started how much better home raised poultry is, and really for the time and effort, it’s well worth it.